Get lifelong value from your filtration system

Every day, we deliver quality process filtration solutions – made with care to your exact standards.

Overcoming the biggest obstacles

Your filtration system is an essential part of your production process. It helps guarantee your final product is consistently high in quality and delivers reproducible results. So, it’s essential you dedicate time to ensuring your system is set up correctly and fully optimised.

An optimised process ensures operations run smoothly, minimises downtime, and safeguards final product quality. However, process filtration is not always straightforward.

This article examines the different challenges you may come across when choosing and optimising your filtration system, and how to overcome them. Give your filtration system the attention it deserves today, and you’ll benefit in the long-term.

The first consideration for your filtration needs is choosing the right filter to suit your process demands. Hhow do you use that filter in a way that ensures optimum performance?

When choosing a filter, it is important to think about it in line with your process. The parameters may look right in the catalogue, but consider what happens both upstream and downstream of the intended filter. Considering those may alter your decision. Filters aren't created equal, so it’s crucial you choose the correct filtration system for your specific process and business need.

Remember to use the expertise of your supplier – they are there to help solve your problem, digging deep into your needs and expectations. Rely on your supplier's filtration expertise to help you choose the right filter.

It might be that your current filter works fine. But when did you last optimise your processes to check you're getting the most out of your system? A large proportion of filters in use today could be improved on or optimised, but often they're left to operate without review.

It may feel like a risk – if your filter is working, why change it? But a fully optimised filtration process will result in a more consistent product quality and reduce your filter usage and running costs.

Without optimisation, there could be variability in the final product, leading to unhappy customers. Or you might not be getting full capacity out of your filters, which will inevitably cost you more.

Amazon Filters recently helped a leading manufacturer of fluoropolymer coatings implement new filtration technology into their production facility. The complex low-friction fluoropolymer formulations their chemists develop required filtering during the production stage to guarantee the necessary quality in terms of aesthetics and final product performance.

The customer wanted to:

The process was changed from gravity-fed to a skid-mounted pumped system using a 3 round 20” SupaClean system. The customer can now process anywhere between 300kg and 1000kg with excellent filtrate quality and lifetime.

The customer had also been using solvents to clean the housings. However, with the SupaClean system, both the product and the filter are contained within a bag, reducing the amount of cleaning necessary.

So, not only did the change to SupaClean improve operator safety, but also achieved a reduction in cleaning solvent volumes and production costs.

The adage ‘buy cheap, buy twice’ has never been more relevant than when choosing a filter. Consider two different filter suppliers; Supplier A charges 3x the price than Supplier B, but the filter from Supplier A will last 10x as long and improve the quality of your product. More expensive is not necessarily better - choosing the correct filter selection is the priority. However, cheaper suppliers may not have the quality systems or technical support required.

Let’s examine the ways you reduce the costs associated with filtration.

Start by optimising your filtration train – you might be using multiple stages of filtration because it’s always been done that way. A review could see that number drop, or a review of the type of filter, could see a later specification of product offering longer onstream life, therefore reducing the cost of filtration and the labour involved in changing each stage. But don’t be afraid to lean on the expertise of your filter supplier – they can help you reduce your costs.

The overall costs of production will often involve more than one person. The person responsible for buying the filter will naturally want to pay less per item, but that may be at odds with the person in production whose main concern is using a filter that lasts as long as possible, to eliminate the need to replace it. While it may be hard to get different departments to agree, consider higher-quality filters regardless of your job function, because of the long-term benefit optimised process filtration offers to your business.

Amazon Filters recently helped an international manufacturer of food additives for both human and animal consumption.

Product purification can be challenging. The final step of the customer’s downstream process is a two-stage filtration system comprising a pre-filter followed by a 0.2µm rated membrane filter.

The old pre-filter would block after processing about 70-80kg of product, often requiring 40-50 single 10” filters to be used per batch. These frequent filter change-outs, in addition to being expensive, resulted in lost product and extended the production cycle due to the time taken to replace the filters.

The company tried SupaPore FPW, both X and V grades as an alternative to the previous pre-filter. SupaPore FPW filters are purpose-designed for protection of downstream membrane filters ensuring that filter system throughputs (lifetimes) are optimised.

Both filters processed up to 250kg of product before replacement was necessary. The throughputs increased by a factor of 3-4 and therefore only 10-12 single 10” filters were required to process a batch.

This is an exceptional improvement in performance, providing significant reduction in spend, a reduction in processing time and an increase in product recovery.

It’s important to keep regulation at the forefront of your mind. Choose a filter supplier who has a deep understanding of the legislation for your sector. This will ensure they supply you with the filtration solution you need to meet those regulations. The best filter suppliers don’t just understand the filtration process, but also the demands of that application in relation to the regulatory framework.

Don’t underestimate documentation. The suppliers who understand the legislation pertinent to your sector will provide the right documentation i.e. Certificate of Conformance. There is also the requirement to use appropriate materials of construction approved to international standards, depending on the industry. For example, pharmaceuticals must conform to FDA regulations; in the water industry, the DWI. This will give you confidence that you're using the right product. Log that in your systems, so that if there are any problems further down the production line, your filter can be fully traceable.

The higher the risk, the greater demand for testing and validation will appear, and with it, an increased level of documentation. And with more testing, comes more documentation. On paper, a low-cost filter may look attractive, but it’s the correct, relevant documentation that matches the demands of the process that you pay for.

Traceability on materials of construction is paramount in ensuring a product will always perform to specification. Where appropriate, you can use the filter serial number to trace source materials and manufacturing process details to give you the necessary confidence in supply.

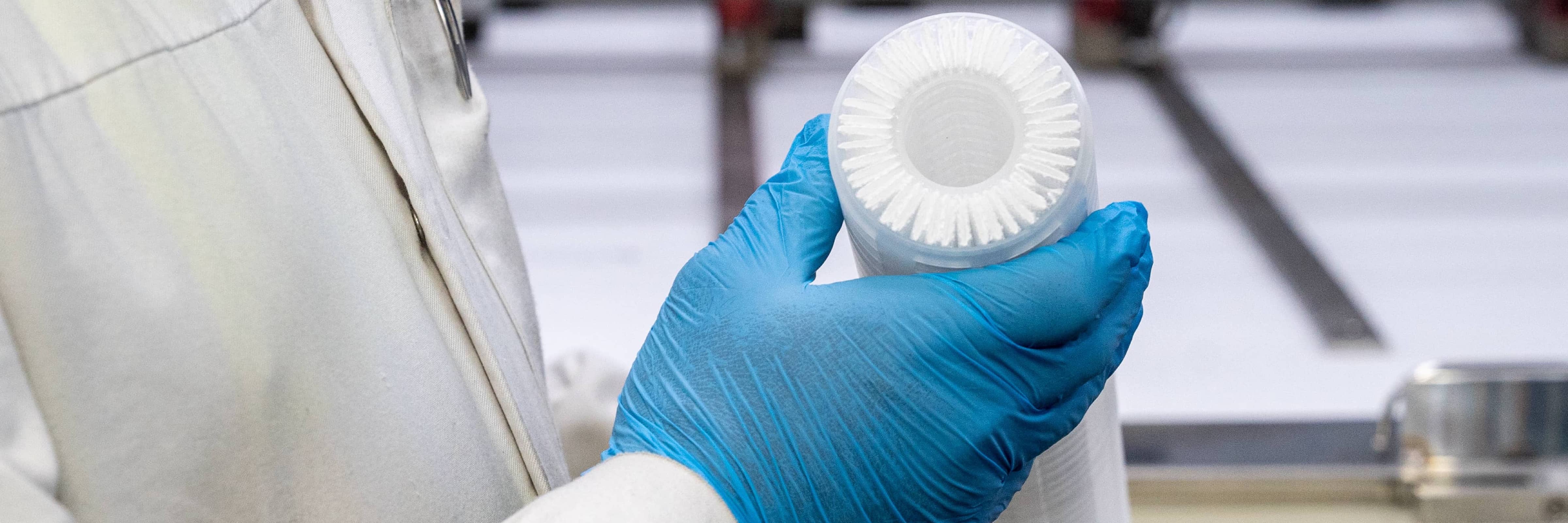

A major manufacturer of an alopecia treatment is using the SupaGard filter to clarify the final product.

While the quality of the SupaGard filter is supported by a comprehensive validation guide and it is manufactured from materials conforming to FDA CFR21 and USP Class VI Plastics, a recent audit by Medicines Regulatory Authorities highlighted the need for additional testing. They required documented evidence that the filter was not altering the quality or safety of the final product based on their specific process parameters.

Often the exact extractables data required and protocols to be used aren't well defined by the regulatory agency and the customer needs support to create the right documentation.

Amazon Filters worked with an experienced network of laboratory service companies specialising in cGMP filter validation and, together with the customer, generated protocols and final validation reports that were submitted directly to the regulator. This approach gives Amazon Filters access to a wider knowledge base for protocol development in tandem with fast turnaround times.

The reports showed that extracted compounds from the SupaGard, under simulated worst-case process conditions, emanate only from the materials of construction of the test filter (polypropylene) and at extremely low levels (10µg/l of product filtered). The filter therefore doesn't affect the quality of the specific product.

The fact that no extraneous contamination was detected on the filter demonstrates the overall cleanliness of the filter and is testament to the quality procedures and clean room manufacturing facilities at Amazon Filters. The final report was readily accepted by the regulatory auditor as proof of the filter being applicable for the process.

No one wants to halt their process for any reason; it incurs costs and limits the amount of product you can produce. Reducing the risk of unscheduled stops is imperative. A reputable filter supplier who has quality systems in place will vastly reduce this risk.

Also, prioritise a filter supplier who can stop everything they’re doing to help you – a supplier that can give quick, technical support in real-time to ensure your process doesn’t need to stop. This will guarantee your customers have a continued supply of your product.

A supplier who understands the whole process – from start to finish – shouldn’t be underestimated. For example, if a filter is blocked, you may assume it’s the filter at fault. But, it’s more likely to be a problem upstream, either in the ingredients of the process or in the pre-processing. Filters are designed to block if there’s a problem. If you didn’t have a filter and something happened upstream, you’d end up with contamination in the bottle, or in the can or in the paint mix for example. A supplier who understands your whole process will be able to help identify when this is the case.

So, although you could go to a distributor or reseller and buy a cheaper equivalent, there’s unlikely to be any deep understanding of your process. You could be using the wrong filter in the first place. Work with suppliers who ask those questions up front to get the most out of your process filtration.

Producing any product can have a serious impact on the environment. Businesses are increasingly required to demonstrate how they're mitigating this impact. Choosing an environmentally friendly filter supplier who considers this in their approach is important. Amazon Filters is currently investigating three initiatives.

We also store and sell the waste produced in the filter manufacturing i.e. off cuts of filter material etc, and recycle them for use in lower spec products such as coat hangers, crates, etc. We've installed solar panels that generate energy for the National Grid, reducing our reliance on conventional energy sources and our carbon footprint. We’re even reducing how much energy we use in our factories and offices by installing LED lights, insulation and new compressors.

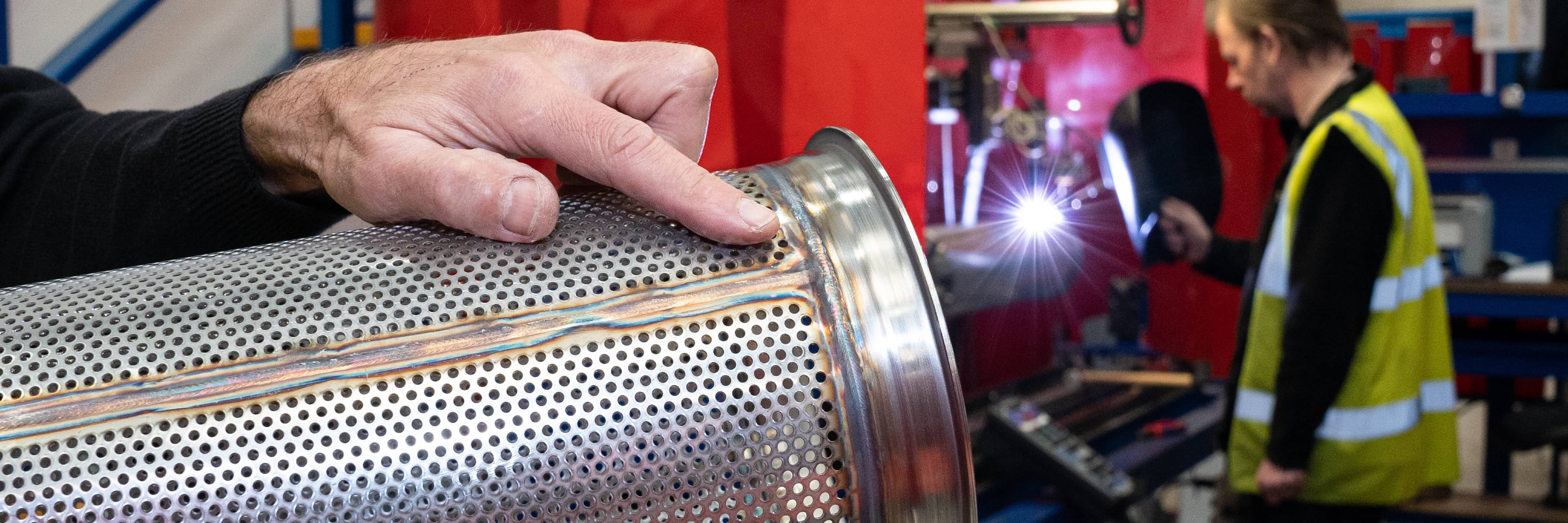

Amazon Filters recently helped a multi-national pharmaceutical company at one of their sites where they produce an API by fermentation of microorganisms.

Due to the need for very high air flows and very low pressure drops, the Off-Gas systems consist of large multi-round housings. Depending on the size of the fermenter they contain either 20” or 30” cartridges. The filters need to operate for as long as possible. Consequently, selecting a filter that demonstrates longevity is imperative. It also needs to demonstrate it can provide sterile air and withstand multiple steam cycles without detriment to performance which could ultimately damage the fermentation process.

We identified that our SupaPore THB cartridge would match or exceed the specification of the existing filter and we supplied a ‘like for like’ in terms size and fit.

After long-term testing, the proven benefits to the client were lower unit costs and a 30% reduction in the clean pressure loss. This lower pressure drop is a significant benefit as it reduces energy costs associated with compressing and temperature controlling large volumes of air.

Due to the high number of filters used each year, the customer had stipulated very specific packaging requirements and Amazon Filters were able to meet that demand, providing double bagged, double labelled filters with a unique bulk supply, reuseable outer package. Another significant benefit for the customer is that by utilising local inventory we can offer shorter lead times and more flexibility in ordering patterns.

The tragic explosion at the Nypro UK chemical plant in Flixborough, changed the industry. Now safety needs to be at the top of everyone’s agenda.

Does your filter supplier comply with the appropriate codes? Do they adhere to and follow national and international standards? Does your supplier know and follow industry guidelines?

Amazon Filters is accredited with the ISO 45001 system which demonstrates the safety features within our own production environment and our products are designed to ATEX requirements.

Preventing contamination or product contact with the operators is also an important consideration. Depending on your industry, you may be filtering something unpleasant and/or harmful. The last thing you want is for your operator to come into contact with an unpleasant substance when they are replacing filters, for example. Operator Exposure levels must follow the strict guidelines set by the Health and Safety Executive. Amazon Filters can support this with products targeted at contamination control, with the environment and operator safety in mind.

Does your supplier prioritise design control to lessen the health and safety risks? Preventing injury and minimising risk must be taken in to account when designing a pressure vessel (and any part of process filtration). Design features, such as quick release clamps, hydraulically operated closures, and retained location devises to minimise parts falling in to a vessel, are all part of the care that should be in a good vessel design.

Speed, value, and quality are the key deliverables for a filter manufacturer. You need to know your chosen manufacturer has fast turnaround times, even if what you need isn’t in stock. Your manufacturer should always have your budget and bottom line in mind and supply quality products, built to last, using the latest technology.

Generic solutions aren’t enough. For large, complex projects, bespoke systems that match your exact specifications are essential.

Custom process filtration lets you fully optimise your processes. A generic filtration solution may not give you the best value. The right manufacturer can conduct a filterability study on a filtration system to see what’s working well, what isn’t, and how to improve the process and get the most value.

Supplying solutions for existing systems is something that every standard filtration manufacturer can do, but not all of them have the technical expertise to do it well. A filtration manufacturer that specialises in custom solutions has the time and resources to produce filtration equipment that works with your existing system.

With a bespoke filtration solutions manufacturer, you can get made-to-order filter housings that complement your custom filtration solution. Filter housings can be designed with ‘plug and play’ functionality, including the exact space or port length you need.

Bespoke solutions also provide the most value over the long term. With a system that matches your exact specification, there will be fewer changes, fewer blockages, and a system that’s designed exactly for you.

Consider how quick and easy it is to speak to an expert. If there’s an emergency, do you know who you could contact for help and how long it would take? Choose a supplier who gives you the confidence that if you need them, they're contactable and available to help.

For over 35 years, our team of experts has designed, manufactured,

and installed innovative process filtration solutions to businesses worldwide.

Today, we’re one of Europe’s leading filter manufacturers. Supported by years of industry knowledge, we deliver high-quality, reliable, and accredited filtration solutions to your exact specifications.

We help you focus on producing high-quality products and services,

and worry less about the filtration process.

Every day, we deliver quality process filtration solutions – made with care to your exact standards.