What micron rating should I select?

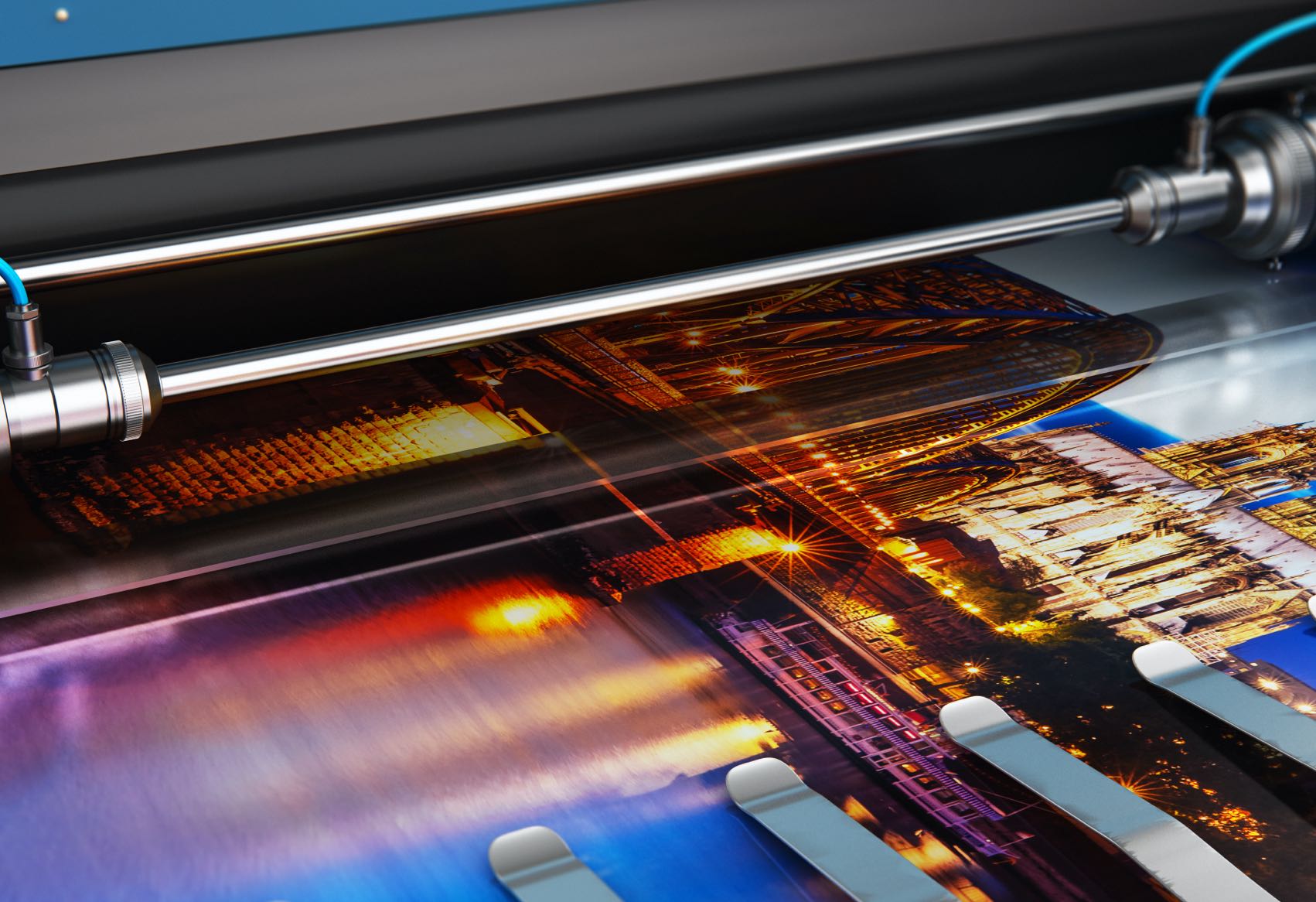

An ACFTD (test dust) in water is usually used to test efficiency at a specified micron rating. Often, this doesn’t relate to the efficiency achieved when filtering complex digital ink formulations.

At Amazon Filters, we’ve assigned efficiency codes linked to the printhead technology. By selecting by printhead, you’ll reduce the risks of blockage in the printhead nozzle.