Let’s get started

We'll make sure you're getting the best out of your process water treatment system.

Water filtration solutions that meet the demands for high-quality process water.

Even where incoming municipal water is high-quality, many industries require it to be purified further so it's suitable for downstream processes. While you might already have purification steps such as RO/UF and UV, if you don't properly control incoming water, it might affect your processes.

At Amazon Filters, we have extensive experience working with OEMs and operators of critical utilities. We make sure water quality is maintained 24/7 with expert water filtration solutions.

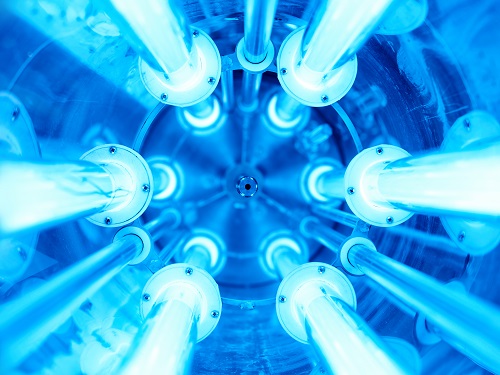

Are your UV disinfection methods not performing? Get the correct pre and post-filtration to the UV step to improve and guarantee disinfection to your exact specifications. Our process water filtration also overcomes the problems of turbidity, particulates, and microbial contamination.

Chlorine in municipal water can degrade your membrane filter systems, which can be costly to replace. We can help calculate the optimum volume of carbon required to dechlorinate water while maintaining adequate process flow. Various grades of carbon are available depending on your application requirements.

Our innovative depth filters for process water incorporate anti-microbial and anti-algae active substances to prevent biofilm build-up. This saves you operational costs by reducing filter usage, production downtime, and the need for filter change out. This isn't just economical. You’ll also improve process water quality by reducing microbial growth caused by continuous movement from solvent-based to water-based coatings and cleaning systems.

Many processes in the production of pharmaceuticals, cosmetics, and beverages require water sterility at the point of use. Installing the correct sterilising grade filter is critical. However, it's important to design the appropriate pipework layout to eliminate dead legs and ensure steam sterilisation is repeatedly effective, while not damaging the filter itself. We can assist in filter selection and general installation design to eliminate costly sterilisation failure.

At Amazon Filters, we're Europe's leading developer of bespoke water filtration solutions. To get a process water solution for your exact needs, talk to us today.

Talk to sales SupaCarb BP

SupaCarb BP

SupaCarb BP cartridges use a unique sintered carbon technology that combines the best features of both powdered (PAC) and granular (GAC) activated carbon in one cartridge.

View product specs SupaPore VPH

SupaPore VPH

The SupaPore VPH is a naturally hydrophilic PES membrane, making it ideal for systems requiring a reliable and consistent high-quality filtrate.

View product specs SupaPore VP

SupaPore VP

SupaPore VP Microfiltration cartridges use a pleated high surface area Polyethersulphone membrane that has been designed for use in a wide range of liquid processing applications.

View product specs SupaSpun II

SupaSpun II

SupaSpun II precision graded density filter elements are a further development of our already well proven absolute rated depth type filter.

View product specs SupaSpun KilBac

SupaSpun KilBac

SupaSpun KilBac® is a range of absolute rated melt blown depth filters with the addition of KilBac® anti-microbial and anti-algal technology to prevent biofouling on the filtration media.

View product specs SupaGard

SupaGard

SupaGard is the latest development in nominal rated spun bonded filter cartridge design.

View product specs SupaGard KilBac

SupaGard KilBac

SupaGard KilBac® is a range of nominal rated melt blown depth filters with the addition of KilBac® anti-microbial and anti-algal technology to prevent biofouling on the filtration media.

View product specs SupaPore Nanofibre

SupaPore Nanofibre

SupaPore Nanofibre filters contain a pleated filter media that exhibits a very high level of positive charge under a wide range of process conditions.

View product specs.jpg?width=200&height=280&name=73-Series-e1431619799610%20(002).jpg) 73 Series

73 Series

The 73 Series hygienic multi stack cartridge housing is available with 3, 5, 8 & 12 element stacks up to 30” long.

View product specs 63 Series

63 Series

Free-standing, simple-to-install design. Easy access to cartridges for fast filter changeout. Find out more about the 63 Series multi cartridge housing.

View product specs 65 Series

65 Series

The 65 Series housing range is designed to accommodate 3, 5 or 10, stacks of filter cartridges up to 40” long.

View product specsAll our products are manufactured in accordance with Quality Standard ISO 9001, Environment Standard ISO 14001 and Health & Safety Standard ISO 45001.

We are committed to manufacturing quality filtration solutions and adhere to the requirements of:

Water

Improved protection of RO membranes in desalination and wastewater reuse: Case Study Read more

We'll make sure you're getting the best out of your process water treatment system.