Let’s get started

We’ll make sure you’re getting the best out of your chemical filtration, solvent filtration, or resin filtration systems.

Get optimum contamination control across your process filtration.

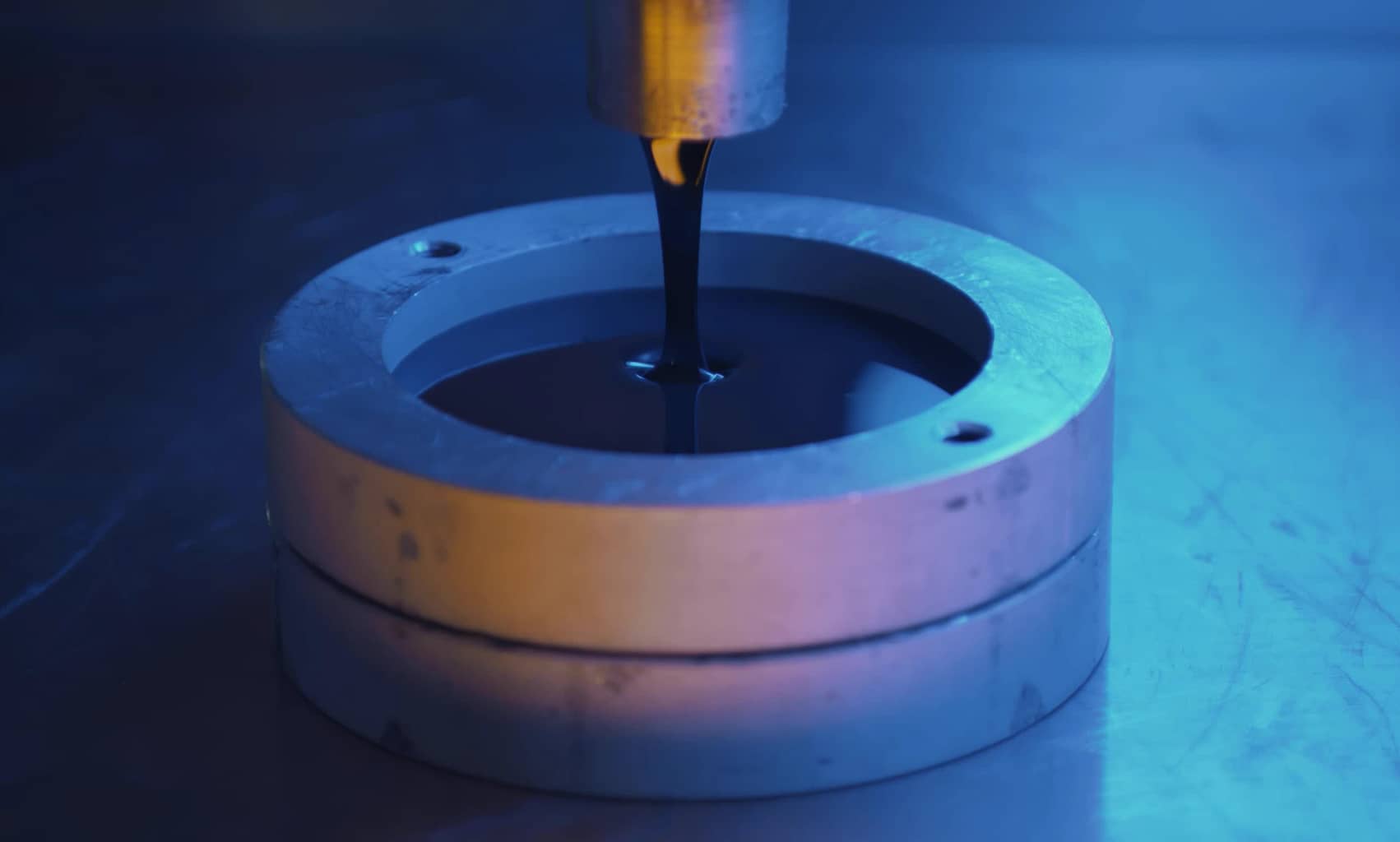

Whether you’re looking for a chemical filters manufacturer, solvent filtration, or resins filtration – we’re here to help. From highly viscous resins to volatile solvents, we have a viable filtration solution for all applications. At Amazon Filters, health and safety are the key drivers behind all our designs. We’re always evolving our chemical filtration solutions to reduce operator exposure and minimise risks.

Highly volatile chemicals can cause problems across containment, compatibility, and also the generation of static. This explosive risk is mitigated by developing the appropriate housing and filter configuration for materials and flow velocities. We also design our chemical filtration solutions with ATEX certification.

If you’re working with highly viscous materials such as PVC sealants, waxes, and mastics in the automotive industry, high-pressure systems are required for their application. Filtration of these products is vital to prevent blockage of the gun nozzles. At Amazon Filters, we’ve developed specialised filtration solutions to overcome these problems.

Processing bulk and fine chemicals is often about the suitability of filters and housing materials. We manufacture our filter housings to provide flexible designs using Duplex, Super Duplex, C22 and 316L stainless steel.

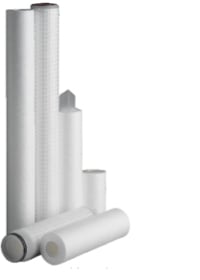

Whether you need filtration for high temperatures, high viscosity, or chemically challenging issues, many choose resin-bonded cartridges (RBCs). These cartridges provide the rigidity you need. The phenolic resins used in the manufacture of RBC's can also pose significant health concerns for those operators involved in their production.

At Amazon Filters, we’re leaders in filtration systems for chemicals, solvents, and resins. Get in touch with us today and start optimising your chemical filtration process.

Talk to sales VisClear II

VisClear II

VisClear II meltblown cartridge elements have been specifically designed for the filtration of chemicals and liquid industrial coatings. More specifically, they are optimised for processing high viscosity and temperature solutions.

View product specs SupaClean Filter System

SupaClean Filter System

The SupaClean Filter System consists of a filter cartridge enclosed inside two sealed bags, ideal for hazardous materials and paint industries

View product specs SupaGard

SupaGard

SupaGard is the latest development in nominal rated spun bonded filter cartridge design.

View product specs SupaSpun II

SupaSpun II

SupaSpun II precision graded density filter elements are a further development of our already well proven absolute rated depth type filter.

View product specs 59 Series

59 Series

The Amazon 59 Series single stack, high pressure cartridge filter assembly is ideal for use with PVC, sealants and waxes that are used in the Automotive and other industries.

View product specs Corrosion Resistant Housings: Tantaline

Corrosion Resistant Housings: Tantaline

Amazon Filters is a leading supplier of filter housings to a wide range of industries including many where effective filtration of chemical products is critical to their operations.

View product specs Corrosion Resistant Housings: Fluoropolymer

Corrosion Resistant Housings: Fluoropolymer

When filtering aggressive chemicals and solvents it is imperative to choose the correct base material, coating or surface modification.

View product specsAll our products are manufactured in accordance with Quality Standard ISO 9001, Environment Standard ISO 14001 and Health & Safety Standard ISO 45001.

We are committed to manufacturing quality filtration solutions and adhere to the requirements of:

Chemicals & coatings

Improving process economics & operator safety in coatings manufacture Read more

We’ll make sure you’re getting the best out of your chemical filtration, solvent filtration, or resin filtration systems.