Let's get started

We'll make sure you're getting the best out of your filtration system

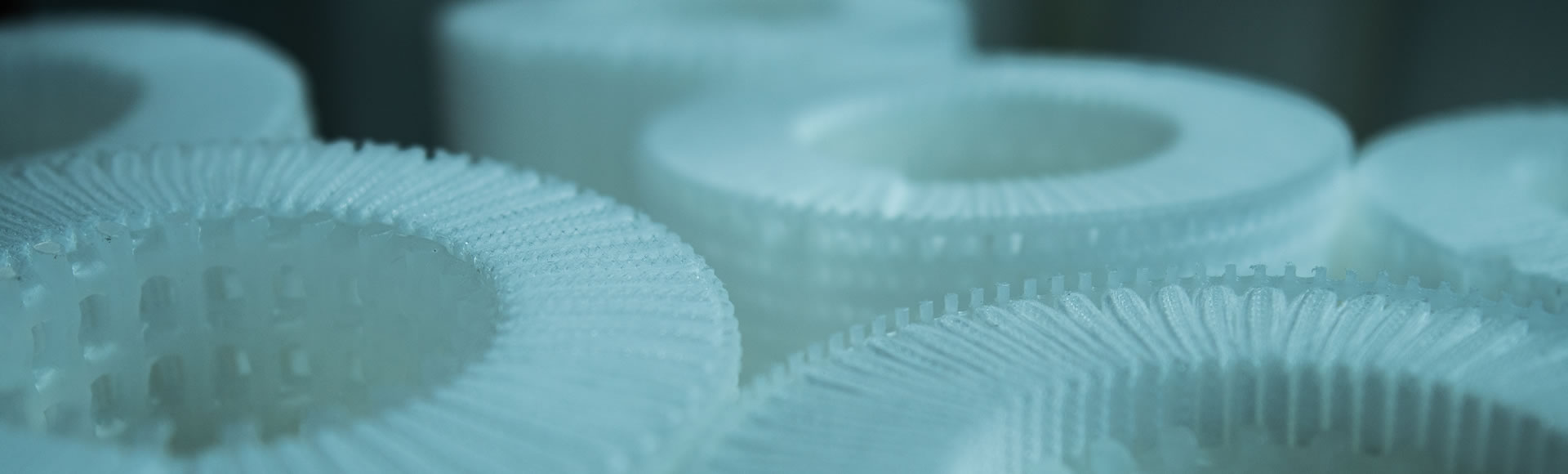

SupaPore PPG

European Manufacturer of Baby Formula Milk

Conditioning of breast milk prior to heat treatment

Germany

Process Optimisation

Healthcare

Premature or preterm babies have complex nutritional requirements which are best served by the complex proteins and complex sugars present in human milk. There are numerous baby formula milks for premature babies on the market, but most are derived from cows’ milk rather than human breast milk. We recently worked with a company working to collect and condition expressed human breast milk which is subsequently freeze-dried for use in hospital neonatal units.

Research indicates that the complex sugars present in human breast milk, but absent in bovine milk, results in infants being 6-10 times less likely to develop necrotizing enterocolitis (NEC). This is one of the most common and serious intestinal disorders that affects 5-10% of all very low birth weight infants.

The manufacturing facility collects and processes milk donations to ensure complete safety and compliance to required standards. The patented process involves separation stages using depth microfiltration to condition the milk prior to heat treatment and, finally, freeze-drying. The filtration process is designed to minimise the temperature requirements on heat treatment and hence preserve the natural benefits of the human breast milk, as well as saving energy.

We worked closely with the company in the scale-up phase of the new process to ensure a viable and optimised depth filtration stage.

Amazon Filters are experts in the development, manufacture, and practical application of depth filtration technology. As such, we have the experience to recommend the most cost-effective pharmaceutical filtration solutions, guaranteeing volume throughput and consistent filtrate quality. We installed a two-stage system using our all polypropylene SupaPore PPG 1.2 onto a 0.45micron.

FDA-approved and USP class VI-compliant materials, coupled with a consistent absolute retention rating of >Beta5000, ensure the milk is processed reliably from batch-to-batch. The SupaPore PPG product range is also supported by a full validation guide providing piece of mind to the customer in such a critical production process.

If you're developing or scaling up a process requiring expertise in filtration, why not give our team a call.

Amazon Filters is able to support filter users in generating the full range of product and process specific Validation Reports required by Medicines Regulatory Authorities. In addition to the Extractables Testing detailed in this case study, Amazon Filters is able to partner with manufacturers to generate Validation Reports on Bacterial Removal Efficiency, Compatibility Testing, and Active Ingredient Adsorption assessment.

For more information, please contact us using the form below or call us on +44 (0) 1276 670600.

We'll make sure you're getting the best out of your filtration system