The results

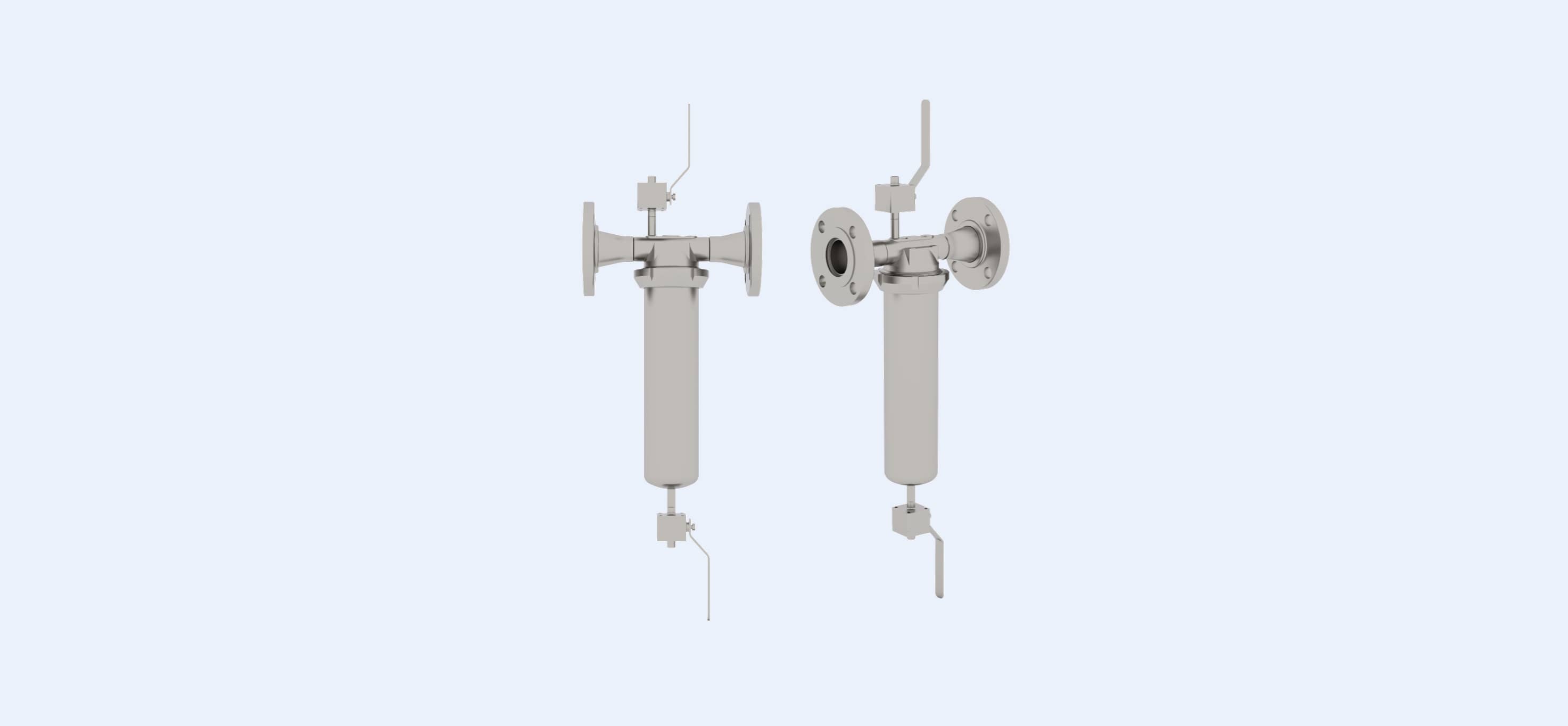

We worked closely with the client to design bespoke, ATEX-approved housings. These housings are explosive-safe and designed to reduce flammable, static, and spark risks common with hazardous chemicals. Additionally, our solution minimised the possibility of operator exposure, helping to protect personnel.

We designed the housing specifically for the client’s exact process. This makes installation simple, helping the client save time and reducing complications.

Our dedicated experts were committed to assuring the efficacy of our solutions. We carefully considered the unique requirements of working with pharmaceutical materials to ensure our housings are:

- Designed for longevity

- Manufactured with the correct materials

- Compatible with a wide range of pharmaceutical fluids

Thanks to our insight, our experts could minimise the number of changes to the housings’ specification. This meant we could settle on the housing design early on, saving time and avoidable costs for the client.