Coalescing filters are critical in any gas application where entrained liquid would cause damage or make a process less efficient. Let's take a closer look at what a coalescing filter is and how it works.

What is a coalescing filter?

Coalescing filters separate liquids from other liquids (liquid-liquid coalescer) or liquids from gas (liquid-gas coalescer). The filtration system speeds up the process of collecting and merging very small droplets of liquid into larger droplets. This makes them easier to remove from the liquid or gas.

There's a crucial difference between the configuration of a coalescing filter cartridge and a standard filter cartridge. With a standard cartridge, gas travels through the filter from outside to inside. This will coalesce the smaller droplets into larger ones, but it won't remove them from the gas stream. It just passes the problem from one side of the filter to the other.

With a coalescing filter cartridge, the process is the opposite. The gas moves up inside the filter and then exits through the outside.

What are coalescing filters used for?

- Removing oil and water from compressed air systems

- Removing liquid contaminants from oil and gas in upstream processing

- Protecting compressors

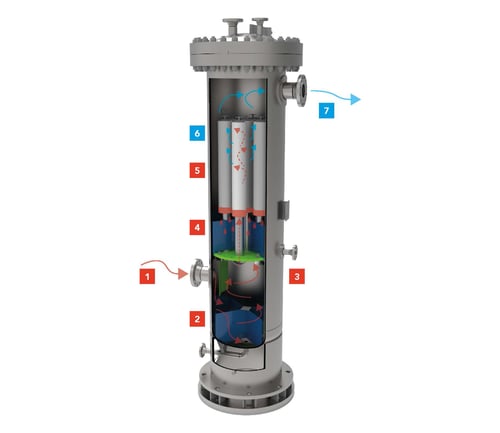

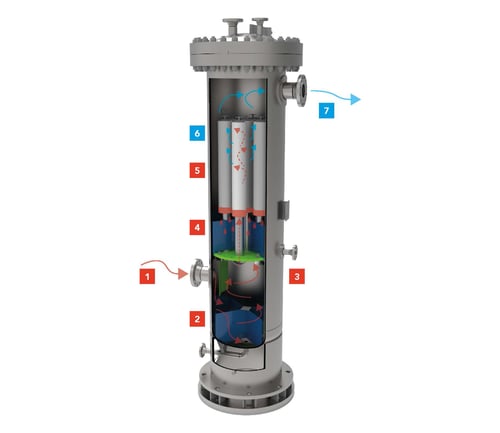

How a coalescing filter works

Let's use a liquid-gas coalescing filter as an example.

- The contaminated gas enters the filter housing.

- Internal impingement plates remove the larger droplets.

- The gas with the smaller droplets travels up inside the coalescing filter cartridge.

- As the gas passes through the filter media, the smaller droplets coalesce into larger ones.

- Large droplets are captured and drained by gravity to the bottom of the housing.

- The coalesced droplets drain out of the base.

- The clean gas exits through the top of the filter housing.

A coalescing filter

Don't discount the importance of coalescing filters

Some companies think they can save money on coalescing filter cartridges by relying on scrubber filters alone. But this is a false economy.

Coalescing filters can save you time and money. Not using them leaves your compressors and turbines vulnerable to damage. It greatly increases the risk of having to shut them down for repairs, causing downtime which can cost your business hundreds of thousands in lost sales.

So, don't be tempted to cut corners on coalescing filters. They play an essential role in protecting not only your compressors but also your process and profits.