Many water-based processes can fall victim to persistent problems with microbial contamination, often leading to bio-fouling of the filtration system.

THE PROBLEM

Many water-based processes can fall victim to persistent problems with microbial contamination, often leading to biofouling of the filtration system. This in turn can cause disruptive problems such as filter blockages, increased differential pressure and release of concentrated microbial contamination, all of which can cause a total breakdown of your production line.

Unfortunately, this is a commonplace problem seen throughout many sectors such as marine, oil and gas, commercial buildings and fuel processes to name a few. In fact, any water-based filtration system can suffer from biofouling, so it’s important to know what it is and how best to protect your systems from it.

How can I prevent biofouling?

How can I prevent biofouling?

Biofouling can be significantly reduced with the help of Amazon Filters. We have developed a brand-new technology to help the industry tackle biofouling at the root of the problem. KilBac is our new range of filter products that include fibres which are compounded with various antimicrobial technologies, therefore inhibiting the growth of bacteria and algae on your water systems.

THE TECHNOLOGY

This new technology is available as a variant of our SupaSpun and SupaGard products; the first two ranges are based on silver/zinc (Ag/Zn) and silver/copper (Ag/Cu).

How does it work?

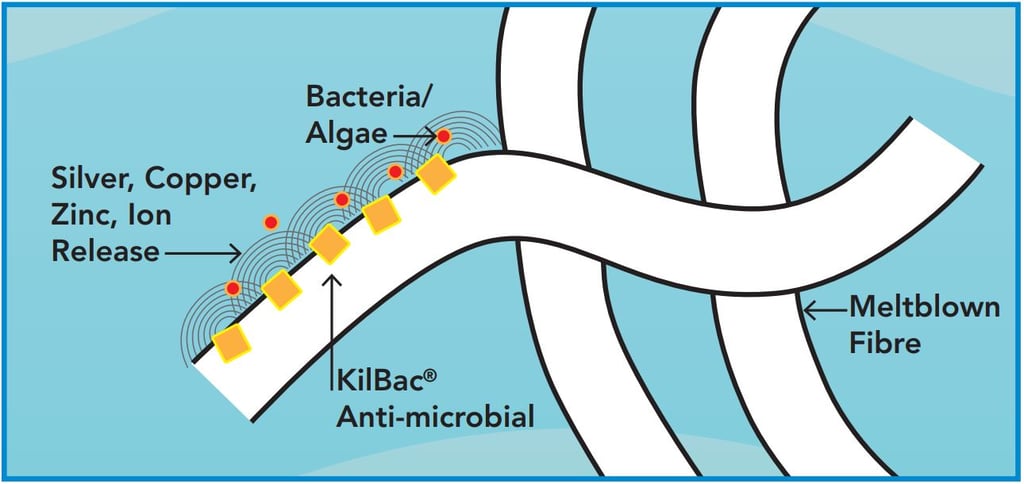

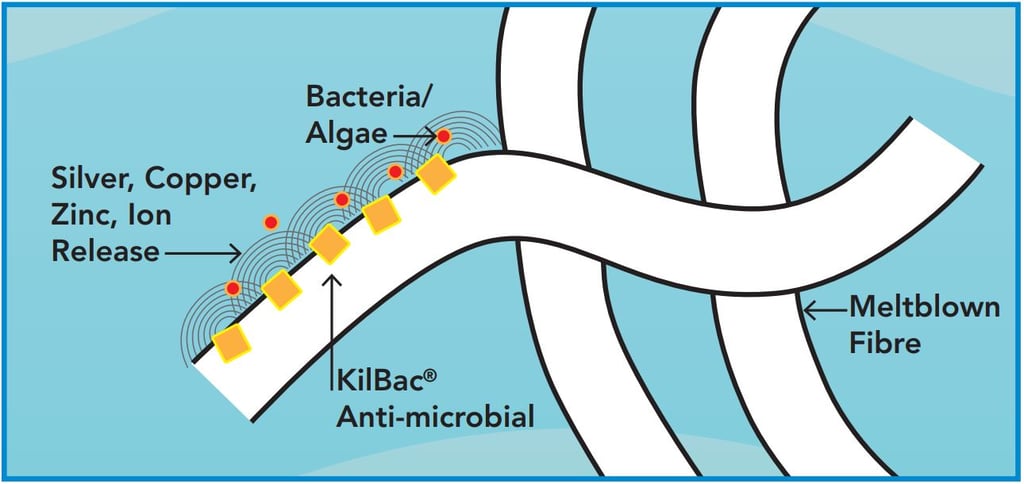

The KilBac fibres take a trimodal approach to prevent bacteria/algal growth:

- Inhibits transport functions in the cell wall

- Inhibits cell division

- Disrupts cell metabolism

These three components work together to eliminate the possibility of bacterial build-up. Our anti-microbial particles are around 5 micron in size, meaning there are no more health and safety concerns over nanoparticles entering the water that passes through your system. By maximising the surface area of these particles, we are increasing the efficiency of their anti-microbial properties by exposing more of the filtered water to them.

Depending on the application, different active elements are matched for optimum results. For anti-microbial applications, a combination of silver and zinc is used, whereas silver and copper are used together for anti-algal applications. These combinations work synergistically and significantly increase the effectiveness of supressing growth on the filter.

Application Notes

What makes ours different?

Our micron sized zeolite particles are manufactured differently to other anti-microbial particles; we take care to maximise their effectiveness as they are being made. Our silver and copper or silver and zinc particles are compounded to the base polymer and controlled during the manufacturing process to maintain a large surface area of these active ingredients providing greater exposure to the water being filtered. Our KilBac filters also come in a blue/green hue making them easily distinguishable.

What are the features and benefits?

- Graded density structure for maximum dirt holding capacity

- Anti-microbial and anti-algal technology

- Eliminates biofouling on filters in addition to controlling overall bioburden in water-based recirculation processes

- Prevents biofilm build-up on single pass systems, extending filter life and reducing overall operating costs

- Range of nominal ratings from 0.5 to 20µm

- Thermal bonding

What are the applications?

Both the SupaSpun and SupaGard KilBac filters are applicable to:

- Seawater applications: pre-filtrations systems for protection of SRP membrane for injection water in Oil and Gas exploration.

- Any process water system where intermittent flow is possible leading to stagnant conditions.

- Filters used in side-stream applications within building services on LTHW, CHW and condensate circuits.

- Prefiltration to hospital equipment such as endoscope washers

THE RESULTS

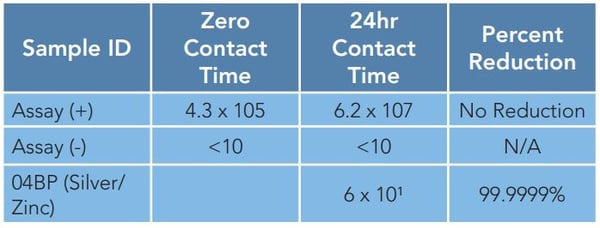

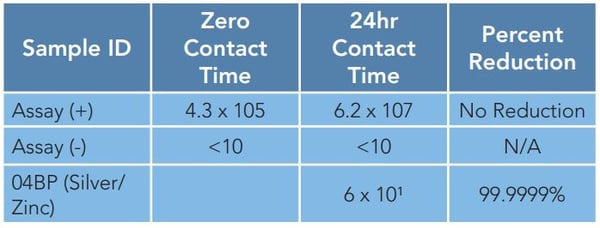

Amazon Filters have conducted many internal studies assessing the efficiency of treatments on a variety of micro-organisms. The ability of the filters to control bacteria growth was evaluated using the ASTM E2149 test method on the SupaSpun KilBac range. For this test, a sample of the filter was placed in a flask containing water and bacteria (pseudomonas aeruginosa). Over the duration of 24 hours, the flask was agitated to replicate intermittent water flow through the KilBac filters. The results are as follows:

KilBac filters can also help with bioburden control in recirculation systems. We conducted testing in triplicate on a recirculating system with mains water running at 5l/min/10”. The results are as follows:

- No increase in differential pressure with KilBac over 2 weeks

- Standard fibres caused over double differential pressure in same time frame

- No proliferation of microorganisms (100’s cfu/ml)

- Best performance at <8l/min/10”: target 5l/min

Not only do our fibres eliminate biofouling and overall bioburden in recirculation processes, they prevent biofilm build-up on single pass systems extending equipment lifetime and reducing overall operating costs.

Find Out More!