Let's get started

We'll make sure you're getting the best out of your filtration system

SupaGard

Large Municipal Water Company

RO Protection on Wastewater Re-Use

Australia

Control of SDI & Extended Lifetime

Water

When large desalination or municipal wastewater treatment plants are designed, the cost per litre is understandably of paramount importance. This focus on reducing costs at every stage of purification can lead to the lowest cost consumable filters being specified. Taking this approach can have a negative effect on the OPEX of the plant if the RO membranes are not adequately protected. In this case study we look at how analysis of blockage profiles through the filtration media helped us develop a filter that could demonstrate increased throughputs and offer a consistent SDI influent stream so as to maximise RO membrane operation service life.

The design of prefiltration stages will vary considerably depending on the location of the plant and quality of the water to be treated. In applications where cartridge depth filters have been specified the use of true graded density filters can increase the service lifetime of expensive RO modules.

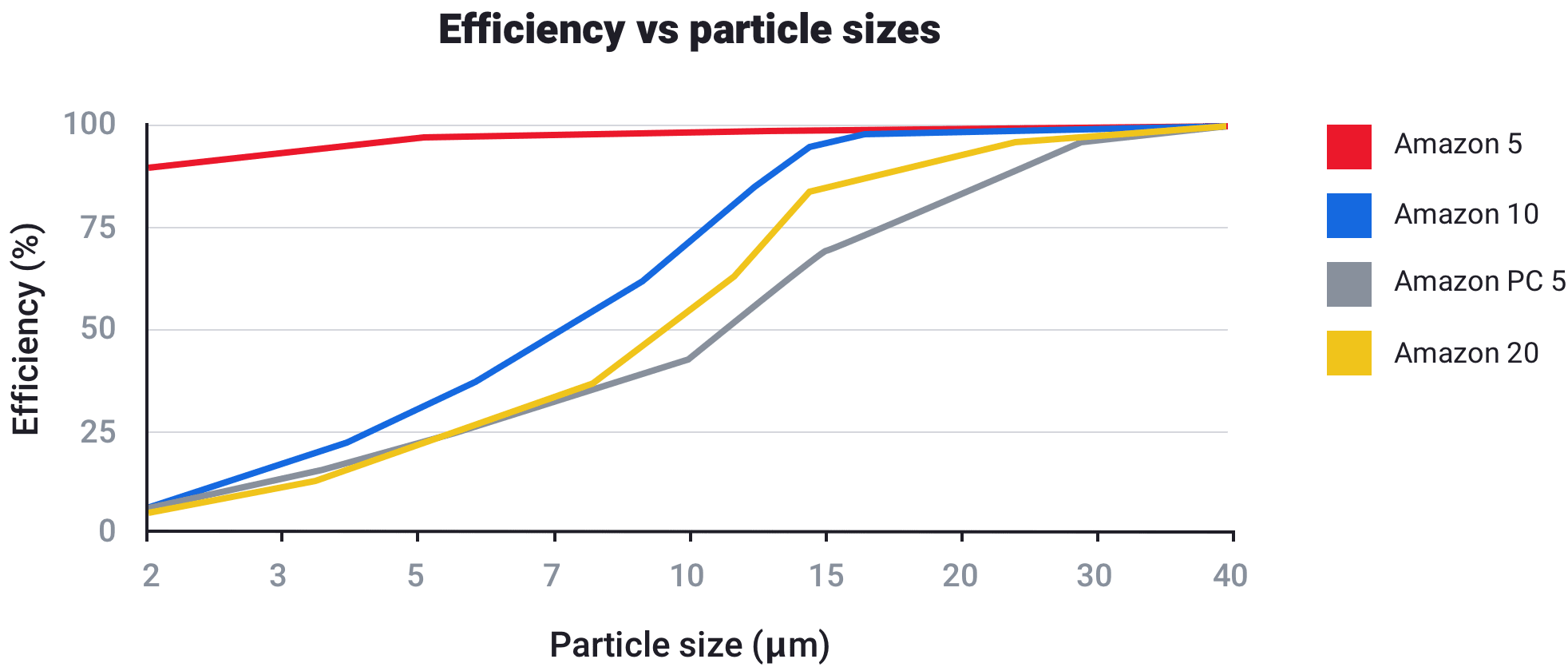

The default choice for RO protection on new plant design is typically a 5µm rated meltblown filter. The problem is that installing a filter with a nominal rating of 5µm in no way informs the user of its true efficiency and potential service life. The first part of the study was to determine the efficiency of the current prefilter to benchmark the existing product. This provided striking but not unsurprising results.

The graph clearly demonstrated the widely different efficiencies at 5µm with the competitive cartridge having an efficiency of 20% compared to 96% for the equivalent Amazon filter of the same nominal rating. It is important to concentrate on the best filter design for the application rather than relying on micron rating alone.

If micron ratings are specified, they need to be linked to % efficiency to mean anything.

Unfortunately, many processes have the micron rating of filters written into SOP’s without reference to efficiency. This can lead to significant differences in performance when changing supplier and comments such as ‘your filter blocks too quickly’. Unfortunately, what can happen is that filters are relabelled to satisfy the SOP rather than the process. This leads to even more confusion as nobody knows what specification of filter is installed!

In this case study the customer required an SDI of < 2.5 prior to the RO membranes to guarantee acceptable service life. With the existing filters there were sometimes excursions up to 5 during service. Our goal was to ensure consistent SDI <2.5 onto the RO while extending the life of the cartridge prefiltration.

A number of prototypes were manufactured and installed in the wastewater treatment plant over a period of 2-3 months. Used filters were returned to the laboratory to analyse the dirt loading profile throughout the depth of the media. This, along with the performance data recorded at the wastewater plant was used to generate new design iterations.

The final SupaGard filter specification achieved consistent SDI results below 2.5 and typically below 2, with accompanying increased filter life and dirt holding capacity.

It is important to focus on the requirements of the process rather than being driven by specifications centred on micron ratings. The use of filters with a true graded density structure allows the best of both worlds in terms of efficiency / protection of RO membranes and maximising service life of the prefilters.

In calculating the overall OPEX of the plant it is worth factoring in the risk of installing basic low cost filters rather than investing in a product that will better protect your RO system.

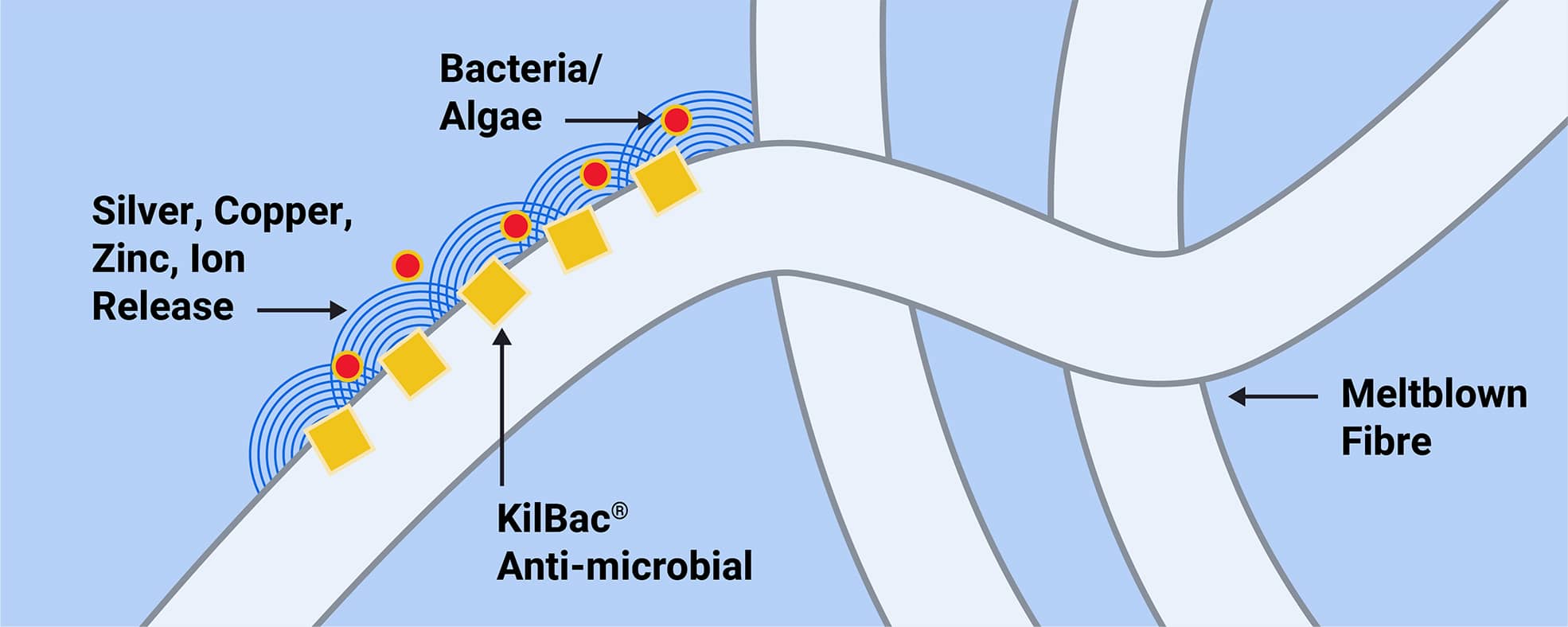

For applications where there maybe issues with biofouling of prefilter cartridges we also have KilBac® variants of our SupaGard range. The antimicrobial and antialgal technology embedded in every filter fibre effectively inhibits growth and prevents premature blockage.

We'll make sure you're getting the best out of your filtration system